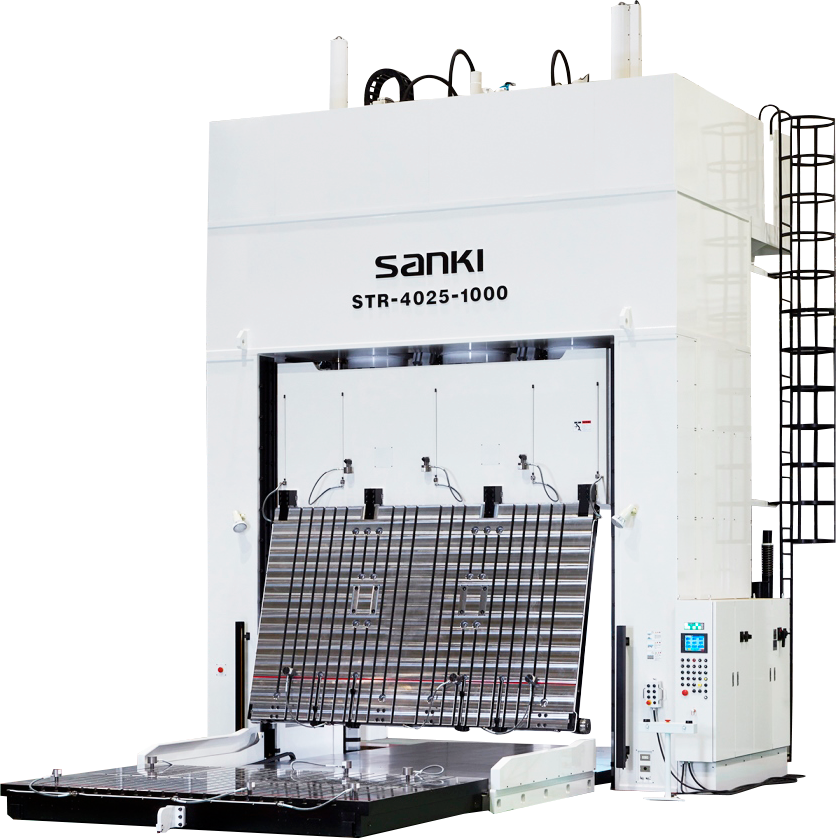

- DIE AND MOLDSPOTTING

PRESS

- Useful for more and more sophisticated mold finishing andshort delivery times.

STR-4025-1000MARSGIBasic Information

Special accessories (options)

- Table moving device

- A device to efficiently carry out metal die exchange by the lower table moving from the press main unit to the exterior.

- Micro-adjust device

- Realizes accurate operation of slides in steps of 5/100mm and high reproducibility which cannot be realized with hydraulic control. Brings into action matching of pierce-type and blank-type blades.

- 180°forward reversing device

- Enables turning the upper mold at arbitrary angles from 0 to 180° and efficient correction of upper mold at time of creation.

- Shock-less device

- Bring into action at time of trial and prototype creation through pierce-type and blank-type. Drastically reduces shocks and noise when under operation.

- Touch panel

- The touch panel on the control panel enables various press controls through touch operation including pressure display and slide position control.

- Eco machine authorization model

- A model which drastically reduces electricity consumption and exhaust heat compared to traditional methods through inverter control of the main electric motor.

DIE AND MOLD SPOTTING

PRESS

product catalog download(PDF)